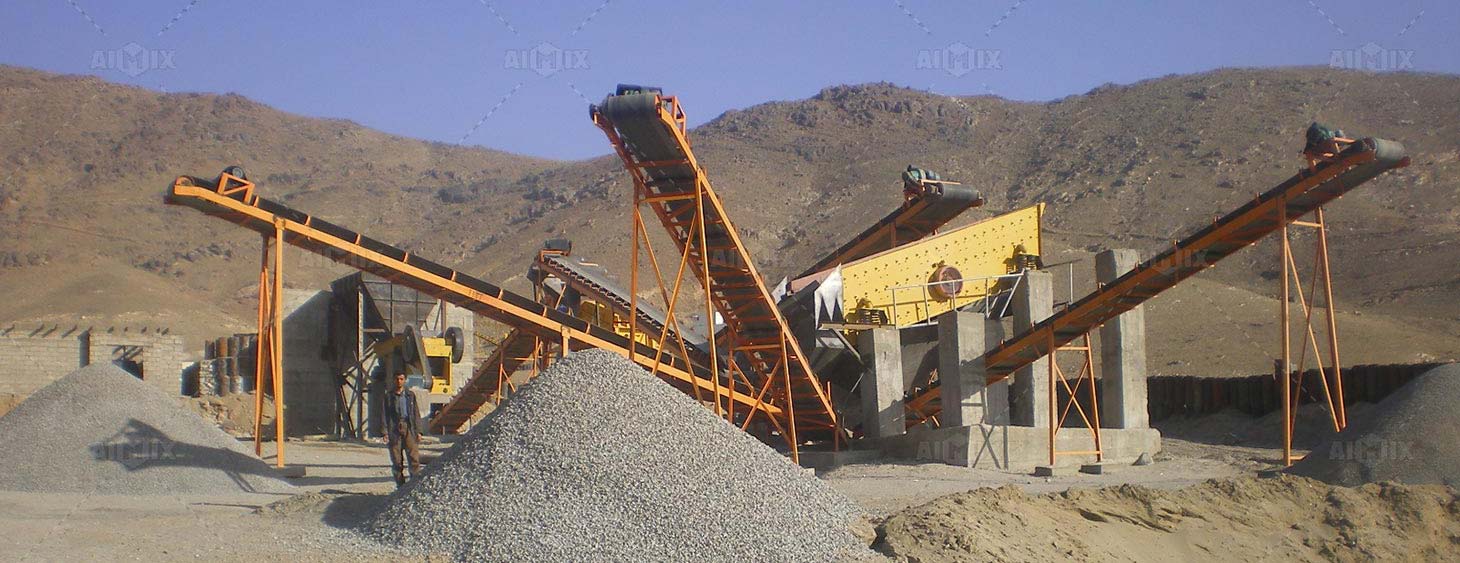

The aggregate industry stands at the precipice of a profound transformation, one that moves beyond incremental improvements toward a complete operational metamorphosis. For decades, gravel crushing has been characterized by its formidable gravel crusher machinery and the skilled, yet often reactive, oversight of human operators. This paradigm is now shifting under the influence of the Fourth Industrial Revolution, or Industry 4.0.

The integration of Artificial Intelligence and sophisticated automation systems is not merely an upgrade; it is a fundamental reimagining of how a crushing plant functions. This evolution transcends simple mechanization, embedding a layer of digital intelligence that empowers equipment to perceive, learn, and optimize its own performance in real-time. The result is a move from brute force processing to a state of graceful, data-driven efficiency that promises to redefine productivity, safety, and sustainability in quarry operations.

The Core of Intelligent Crushing: AI-Driven Process Optimization

At the heart of this revolution lies the application of AI and machine learning algorithms to the very process of comminution. These systems move far beyond pre-programmed logic, introducing a dynamic and adaptive intelligence to the crushing circuit.

Predictive and Prescriptive Analytics in Action

Modern AI-equipped crushers are outfitted with a network of sensors that continuously monitor a vast array of operational parameters. These include crusher load, power draw, pressure, vibration spectra, and even the acoustic signature of the machinery. An AI system does not simply log this data; it synthesizes it to build a profound understanding of cause and effect. It can predictively identify the optimal aggregate crusher speed and closed-side setting for a specific feed material’s hardness and size distribution, maximizing yield of the desired product fractions. More advanced systems offer prescriptive analytics, not just flagging a potential bearing failure based on a subtle change in vibration patterns but also recommending specific operational adjustments to mitigate stress until scheduled maintenance can be performed. This transforms maintenance from a calendar-based chore to a needs-based, predictive science.

Automated Closed-Loop Control Systems

The ultimate expression of this intelligence is the implementation of closed-loop control. In a traditional setup, an operator might notice a change in product size and manually adjust a setting. In an automated AI system, the process is seamless and instantaneous. Vision systems or laser scanners analyze the output material on the conveyor belts, providing real-time feedback on particle size distribution. The AI then cross-references this with the current machine settings and feed conditions, automatically making micro-adjustments to the crusher to maintain a consistent product specification. This creates a self-correcting production line that operates at its peak efficiency around the clock, entirely independent of operator shifts or fatigue, ensuring unparalleled product consistency.

Enhancing Operational Safety and Human-Machine Collaboration

The integration of smart technology brings a monumental leap forward in operational safety, creating a more protective and less hazardous environment for the workforce.

Proactive Hazard Mitigation and Site Awareness

AI-powered computer vision systems can be deployed throughout the plant to act as an ever-vigilant guardian. These systems are trained to recognize unsafe behaviors or conditions, such as a person entering a designated exclusion zone around a powerful crusher or a loader operating without its beacon active. Upon detection, the system can trigger immediate alerts, sound alarms, or even send a shutdown signal to the nearby machinery. Furthermore, the extensive automation of material handling—controlling conveyors, feeders, and screens through a centralized Programmable Logic Controller (PLC) system—minimizes the need for personnel to be in close proximity to high-risk areas. This creates a fundamental shift from reactive safety protocols, which depend on human vigilance, to a proactive, engineered safety environment that is inherently more robust and reliable.

The Evolving Role of the Plant Operator

With AI handling the minute-to-minute optimization, the role of the rock crushing plant operator is elevated from manual controller to strategic overseer. Freed from the constant demand of adjusting levers and monitoring individual gauges, the operator can focus on higher-level tasks. Their purview becomes system performance, analyzing trends provided by the AI, managing logistics, planning maintenance windows, and intervening only for complex exceptions or strategic overrides. This human-machine collaboration leverages the unique strengths of both: the relentless, data-processing power of the AI and the nuanced judgment, experience, and problem-solving capabilities of the human expert. It is a synergy that fosters a more engaging and intellectually demanding work environment.

The Tangible Benefits: A New Era of Quarry Profitability

The convergence of AI and automation delivers a compelling return on investment through multiple, interconnected channels that directly impact the bottom line.

Maximizing Yield and Minimizing Waste

One of the most significant financial advantages is the drastic reduction of waste and the maximization of valuable product yield. By maintaining a consistently optimal crusher machine setting, the AI ensures that a higher percentage of the raw feed is transformed into saleable product, minimizing the creation of unwanted fines or oversize material that must be re-crushed or stockpiled. This precise control over the crushing process directly translates to more tons of high-quality aggregate produced per ton of raw feed, a fundamental metric of quarry profitability. This precision is the hallmark of a truly modern and efficient operation.

A Sustainable and Future-Proof Operation

The benefits extend beyond mere economics. An intelligently optimized plant consumes less energy, as the crusher is no longer operating under inefficient, overloaded, or underloaded conditions. It also reduces wear on consumable parts like mantles and liners, as the AI avoids damaging operational states. This leads to a longer equipment lifespan and a reduction in the environmental footprint associated with manufacturing and shipping replacement parts. Embracing this technology is not just about competing today; it is about future-proofing an operation. It builds a resilient, data-centric foundation that can adapt to new market demands, regulatory requirements, and technological advancements, securing the long-term viability and competitiveness of the business in an increasingly digital world.